By 2021, the global spending on the Internet of Things is forecasted to cross $1.4 Trillion, as per the reports generated by a reputed online portal- Information Matters.

One more report by Statista, another famous market research portal, depicts that the market revenue of IoT in 2017 was $100 billion and by 2025, it will cross $1.6 trillion.

These figures are huge and growing at a fast pace due to the usefulness of IoT in various industrial sectors. The transparency, real-time visibility, automation, smart data insights, and much more that IoT offers, have helped sectors like manufacturing, transportation, healthcare, supply chain management, agriculture, etc. to become more efficient and profitable.

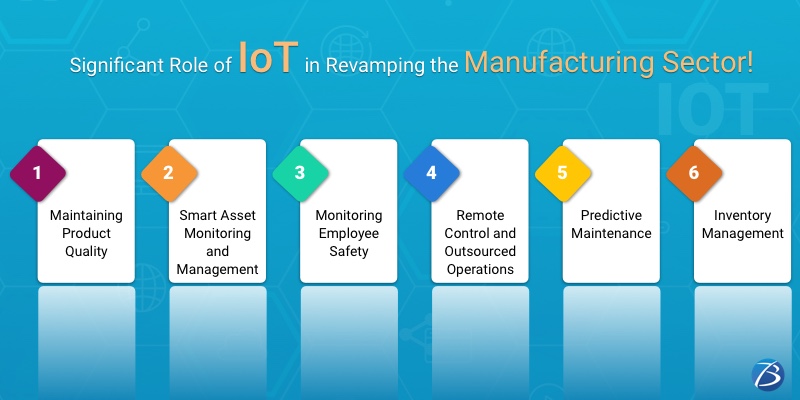

This blog-post focuses on the significant ways how IoT app solutions have influenced the manufacturing sector and helped companies accelerate productivity, reduce costs, enhance product quality, and deliver on time. But before getting started, let us quickly look at the challenges faced in this sector.

Challenges in the Manufacturing Industries!

- Stronger demand for customization

- Rising customer expectations

- Concerns regarding employee safety

- Inability to develop high-quality products

- Slower time to market

- Complexity in the supply chain on a global level

- Data interoperability issues while migrating from legacy systems

IoT in Manufacturing Industries!

Maintaining Product Quality

During production, identifying defects and inspecting process flows, etc. is essential for maintaining the best possible quality of products. Implementation of IoT helps in the identification of defective products and also helps monitor the process cycle. This data allows the managers to take proactive manufacturing decisions, thereby preventing quality issues and thus, maintaining the brand value by developing high-quality products.

Smart Asset Monitoring and Management

If carried out manually, asset tracking can consume a lot of time and there are high chances of errors or missing data at times. But with IoT devices and technologies like Barcode, RFID, NFC, etc. traditional methods can be replaced by smart tracking methods. It helps to gather real-time accurate data from assets like a crane, machines, smart totes, smart shelves, equipment, etc. It gathers data like their locations, their quantity, their movements, etc., and this data is sent to employees through IoT app solutions for utilization.

For implementing asset tracking, every asset in the company is labeled with an RFID tag that acts as an asset identifier. Every tag comes with a unique ID and whenever an asset moves in or out of a defined area, the tag is scanned and records are saved on the system for the concerned employees to use this data. This helps the manufacturers achieve asset visibility and accountability while saving a huge amount of time for employees.

Monitoring Employee Safety

Workplace safety in sectors like oil and gas, transport, mining, and other manufacturing companies is critical for a healthy environment in the company. IoT sensors, wearable devices, RFID, etc. play a significant role here. The safety teams can rely on IoT-based systems to identify sudden or unknown safety risks to take the required measures proactively. Such efforts will also help to reduce compliance claims and costs associated with the risks.

In several companies, workers are provided with RFID tags and wearable devices to keep monitoring their locations, as well as data like temperature, heart rate, galvanic skin response, etc. This data is relayed to the cloud to identify any unusual patterns like fluctuations in the heart rate, sudden vertical movements, overheating effects, etc., and used for preventing the workers from any threats or injuries.

Remote Control and Outsourced Operations

Centralized supervision is possible with IoT systems and several giants in the manufacturing sector are using them. Vital data can be collected through distant control and it provides intelligent insights into the actual production field. Thus, IoT enables monitoring the workflows, controlling the switches of the machines, and thus, ensuring safe automated production.

Also, in case a company sets up their manufacturing company in a different state or city, it is vital to maintain the same product quality. In this case, too, the remote controlling ability of IoT systems can be brought to use. These methods help the manufacturers keep an eye on the efficiency of the products in real-time from a distant location.

For example, COREIoT Workforce Management Solution is a turnkey project that provides advanced tracking and monitoring facility thereby ensuring complete visibility of the workforce in the organization.

Predictive Maintenance

A study by Deloitte says that IoT-based predictive maintenance solutions can reduce maintenance costs of the factory equipment by about 40% and by 2025, it can generate an economic value of $630 billion per year. It is obvious from these numbers why IoT is being adopted by countless businesses for maintenance.

It is of utmost importance for the companies to track the abnormalities in the machinery or monitor any machine failures, well in advance. In case these are not tracked beforehand, they can cost a fortune to the company. In this scenario, predictive maintenance with IoT or Conditions Based Maintenance (CBM) comes into the picture. IoT sensors can be employed to continuously monitor the actual conditions of the machines and send the data to IoT- applications. As a result, any signs of machine failure can be detected in advance by the concerned staff and its maintenance can be scheduled accordingly; thus saving the company from huge monetary losses in the future.

Inventory Management

IoT-powered inventory management solutions can help track and locate products/equipment/raw material from large warehouses in a very short time. These solutions help the manufacturers to ensure constant visibility into locations, quantity, and statuses of the inventory, automatically track them and send reports to the mobile apps or company systems, and properly optimize the time between the order and delivery of the inventory items. It minimizes inventory out-of-stock situations, as it helps to re-order the inventory at the appropriate time.

Thus, IoT simplifies inventory management and does it with higher accuracy while saving vital time for the company.

Final Words:

Maciej Kranz, Vice President of Strategic Innovation, Cisco quoted, “[Leading manufacturers] are getting ROI primarily from applying IoT for connected operations, remote operations, predictive analytics, and preventive maintenance.”

As said in this quote, several firms have been radically transforming their operations and improving their bottom line with IoT app solutions. By successfully integrating the right IoT applications, manufacturer scan resolve complex challenges in the sector, and thus, serve their customers in a better way. Owing to this, the industrial sector is witnessing a rising number of IoT application development companies and smart IoT app developers all over the world.

That’s it for this post.

Hope you liked it. Do share your views with us.

Also, is there any other vital application of IoT in the manufacturing sector that you know, do let us know by commenting below.