TL; DR: The future of packaging is digital. AI and smart materials are helping to reduce waste and improve efficiency, but the biggest change isn’t the technology itself—it’s the way we think. We need to use these tools to create a world that’s circular, transparent, and sustainable.

Explore how technology is addressing the global food packaging waste problem: the advantages of smart materials, the dangers of not acting, and a plan for a more sustainable future.

Key Takeaways

- Technology is moving beyond just recycling to build a complete system of sustainable packaging.

- Innovations in biodegradable materials, smart packaging, and AI-based design are cutting down on waste and helping food last longer.

- Lack of clear policies and proper use of technology creates risks like consumer confusion, inefficient supply chains, and more waste.

- Blockchain and data analysis help track materials from where they come from to where they end up, ensuring honesty and responsibility.

- A balanced plan that uses material science, smart design, and data insights allows companies to go green without sacrificing quality.

The Journey from Plastic to Progress

Discovering the Power of Smart Design.

In the past, food and beverage packaging was mainly about cost and convenience. Plastic was the go-to choice, and sustainability was often overlooked. Today, we produce over 450 million tonnes of plastic worldwide , and a lot of this waste feels unavoidable. The challenge seemed impossible—how could we protect food, keep it fresh, and please customers without hurting the planet?

The answer came not from a new material, but from a new way of thinking.

The arrival of new technologies felt like a breakthrough. It was like a highly skilled designer joined a team, creating packaging ideas based on complex data. The old, time-consuming trial-and-error process that used to take up mornings was replaced with smart insights, leading to a 15% drop in material waste during the design stage. Deadlines for launching new, eco-friendly products were met with ease. This new approach started creating a new group of “sustainable innovators.”

The early promise of these new design and material technologies matches the growing interest in the industry: more and more companies are looking to include them in their operations.

Encountering the Hidden Risks of Inaction

Yet the initial excitement can hide real dangers.

During a check on a new “biodegradable” packaging, a problem was found. The material was meant to break down in a commercial composting plant, but it didn’t work well in most home compost systems. This led to confusion among consumers, and the package ended up being thrown away. The team trusted the supplier’s claims instead of checking the material’s features themselves. This mistake caused a 10% rise in production costs because of the material’s incompatibility and the need for a redesign.

Each new version looked good at first—until it wasn’t.

Weeks went by as the team tried quick fixes. It wasn’t until they studied material science that they realized their product was only “eco-friendly” in very limited situations. This issue is common. A recent OECD report shows that just 9% of plastic waste is recycled worldwide , showing the big difference between what people think and what actually happens. This experience was a wake-up call: technology doesn’t replace careful engineering. It just makes it faster when you combine it with thorough checks.

Understanding the Limitations of Eco-Friendly Claims

The faulty packaging served as a key lesson: a claim can be unclear.

Manufacturers gather data from lab tests, but they don’t always think about the bigger picture the way humans do. As top research groups point out, new materials can make production more efficient but can also bring up new issues like safety, legal requirements, and ethical concerns that need constant attention. If not properly monitored, these new materials might not work as intended, could create hidden problems, or might break local rules about how things should be disposed of.

Best Practices for Using Technology in Packaging Development

Technology should be seen as a helpful partner, not a replacement for human judgment.

To use it effectively without sacrificing quality, companies should follow these guidelines in their process:

- Start with design, then move to production: Begin by creating lifecycle analysis diagrams and material flow maps before developing any new packaging designs. This helps ensure that the technology’s recommendations fit with the company’s goals and help cut down on unused materials. This helps ensure that the technology’s recommendations fit with the company’s goals and help cut down on unused materials.

- Check everything thoroughly: Think of a new material like a first-time contributor’s code. Carry out detailed testing and evaluation of how the material can be disposed of, ensuring it is easy to recycle or compost.

- Test thoroughly and consider all possibilities: Technology doesn’t understand real-world use or local recycling systems. Create a wide range of tests, including situations that AI might not think of, to make sure packaging works well and stays friendly to the environment.

- Stay aware of the environment: Make sure any new packaging can be handled by current recycling or composting facilities. This helps keep waste out of landfills and supports sustainability goals.

- Keep your brand safe: Don’t share your unique designs or materials with outside tools. Ensure any generated content follows legal rules about intellectual property.

- Keep improving and checking regularly: Use tools that automatically review sustainability and follow company policies. This helps find new problems that might come from design tools and keeps track of efforts to lower the environmental impact.

Career Advice for Junior Professionals

For new professionals, a new technology can seem like a shortcut.

It provides support, but it doesn’t replace the basics. To build a long-lasting career, you should focus on these key areas:

- Material science and engineering: This is the foundation of solving problems. Knowing how materials behave and how they affect the environment helps you assess if a technology is eco-friendly and how much it contributes to carbon emissions.

- Design for Disassembly and Recycling: Learning to create systems that can be easily taken apart and reused. This helps increase recycling rates and makes products more sustainable.

- Supply Chain Management: Understanding how to build systems that can grow and adapt smoothly. This involves managing everything from where materials come from to how products are delivered, with the goal of making things more efficient and cheaper.

- Critical Thinking: Always question the outcomes of technology. Ask for various solutions and compare them, taking into account factors like waste and environmental effects.

- Using Technology as a Mentor: Don’t just ask for the solution, ask why and how it works. Compare different ways of implementing solutions and learn from the differences, especially when it comes to how sustainable they are.

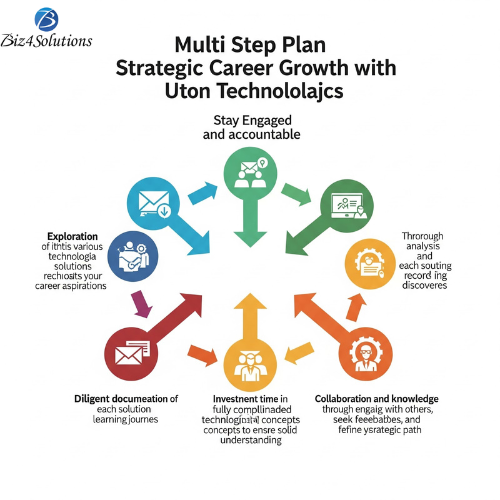

Strategic Career Growth Using Technology

A Step-by-Step Plan for Professionals to Use Technology in Their Career Development: To make the most of technology for career growth, professionals should follow a clear plan:

- First, look for multiple solutions: When faced with a problem, use a design tool to come up with several different ways to solve it. For example, consider both paper-based and bioplastic options, and think about how each might help reduce waste.

- Next, analyze and compare each solution: Look at how well each option performs, how easily it breaks down, and how much it costs. Use factors like carbon emissions, water use, and how easy it is to recycle to make smart choices.

- Keep a record of what you learn: Write down your experiences with technology, noting what worked, what didn’t, and why. Pay special attention to how these experiences affect sustainability goals.

- If something is complicated, take the time to fully understand it: For instance, study the entire life cycle of different packaging materials and how they affect waste in landfills.

- Work with others by sharing your ideas and getting feedback: Talking through your work with colleagues can help you see things you might have missed and build a better understanding of sustainable design.

- Stay interested and responsible: Keep learning about new materials and their effects on society. Use technology wisely, with respect for how people behave and how waste is handled, and aim to improve customer satisfaction with sustainability efforts.

Case Study: Success and Failure in Sustainable Packaging Projects

Let’s look at two different situations:

Success: A group of people from different areas at a new drink company used AI tools to come up with better bottle shapes. They focused their human work on finding materials and testing them. The team checked every design carefully, made sure all tests were done properly, and used technology to try out new ideas. They ended up with a new product that had a much smaller environmental impact, cutting the carbon footprint by 20% . The team also felt more satisfied with their work. This effort also improved the efficiency of their supply chain by 15%.

Failure: Another team, spread out across different places, mainly used AI to design a new container for food. They didn’t do in-depth checks on the designs. A key material issue wasn’t caught before production, which caused the product to spoil faster reducing its shelf life by 5% . This led to a big product recall. The company had to spend several months redesigning the container, lost customer trust, and faced an 8% rise in costs because of the recall.

These examples show that technology isn’t automatically a solution or a risk.

The results depend on how carefully a company uses the technology and tracks its effects through key performance indicators.

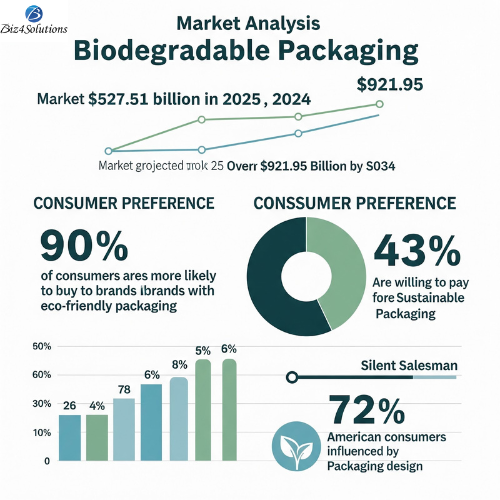

Statistics: The Packaging Revolution

Recent surveys and studies show that sustainable packaging has become more common in the mainstream market.

- The market for biodegradable packaging is growing quickly, expected to increase from $527.51 billion in 2025 to over $921.95 billion by 2034 , showing a clear change in what people want in terms of packaging.

- Consumer attitudes are also shifting: A 2025 Shorr report found that 90% of consumers are more likely to buy from a brand if it uses eco-friendly packaging. Also, 43% of consumers are willing to pay more for products that come in sustainable packaging.

- Another study found that 72% of American consumers say the design of packaging influences their buying decisions, highlighting its role as a “silent salesman.”

- New packaging technologies are making a real difference in reducing waste. For example, better packaging designs can help prevent around 1.1 million tons of food waste each year in the US , which reduces CO2 emissions by about 6 million metric tons. This is supported by smart packaging, which can extend a product’s shelf life by an average of 15% .

- The number of companies using these new packaging technologies has risen from 44% to 62% year-over-year, showing how quickly the industry is adopting these solutions to cut down on material waste and improve recyclability.

Final Thoughts: Steering a Sustainable Future, Not Just a Product

Technology is changing how we design packaging. It helps with routine tasks, sparks new ideas, and—when used thoughtfully—can improve life for both customers and designers. However, technology alone isn’t enough. Companies still have a responsibility to act. They need to be innovators, not just makers. They should look at things as a whole, avoid dangers, and support ethical choices. They must also track their progress through key performance indicators like reducing waste, improving efficiency, and boosting customer happiness.

As professionals move forward in their careers, they should keep in mind that technology is a tool, not a substitute. Using it wisely can help them grow their skills, save time for bigger ideas, and keep their abilities strong. This approach not only helps them stay relevant but also puts them in a position to drive the next big changes in innovation—changes that focus on sustainability and real, positive effects.

Call to Action: What do you think about how technology is shaping sustainable packaging and why tracking KPIs matters? Share your thoughts in the comments below. If you want more insights and useful frameworks, subscribe to our newsletter for regular updates on AI-driven career development and sustainable business strategies.