How is Blockchain Reshaping the Grocery Industry

Grocery shopping has undergone a major transition with the online grocery model gaining prominence. As commerce shifts unavoidably online and consumer demands continue to grow; the process of establishing and maintaining customer trust has become more difficult than ever. Consumers have an extensive array of options available to them and so, they now anticipate complete transparency regarding the products they purchase. The question lies in whether the item truly aligns with its advertised description, whether it has been appropriately refrigerated during transportation to the store, and if it was genuinely produced organically.

The susceptibility of the global food system to various political, economic, and environmental risks has been highlighted by recent events such as wars, the CO.VID-19 pandemic, climate change, and escalating inflation. Consequently, the convenience, affordability, and diversity that food consumers have become accustomed to are now at risk. To put it aptly, a significant portion of the $5.7 trillion worldwide grocery industry is facing significant challenges. Despite its annual growth rate of approximately 4.5 percent over the past decade, this growth has been uneven and has concealed underlying issues.

Thankfully, there is a potential technology that might come to the rescue. An optimal solution with an intelligent supply chain capability that seamlessly integrates and connects all participants within the ecosystem. You might have heard about Blockchain. Blockchain, known for its impact on cryptocurrency markets, is now set to revolutionize the food industry, presenting an opportunity for modernization and transformation. So, let s explore the potential of Blockchain in the grocery industry.

Why should you consider Blockchain for the Grocery Sector?

Blockchain technology is a valuable tool that has the potential to enhance future policies, traceability, and the efficiency of grocery supply chains. Blockchain grocery initiatives have the potential to improve consumer trust, accelerate production processes, and enhance overall product efficiency, addressing current needs and challenges in the industry.

Blockchain has the capacity to bring about significant improvements in global grocery supply chains. It enables faster and more cost-effective product deliveries, enhances supply chain transparency and traceability, and facilitates real-time coordination between trading partners; thereby upgrading the efficiency of the entire system. So, what is Blockchain technology? Let s take a look!

What is Blockchain Technology

The term blockchain has become a popular topic of discussion lately. But what exactly is Blockchain? It refers to a decentralized network that securely records, stores, and encrypts data blocks. These blocks are interconnected in the form of a chain using a cryptographic technique, a branch of mathematics known as cryptography. This cryptographic mechanism serves to safeguard transaction details, preserve user privacy, and encrypt communication between parties. Together, they create a chronological digital ledger where every transaction possesses a cryptographic signature called a hash. Transactions are grouped into blocks where every block carries a timestamp and a link to its previous block.

The verification of data blocks in a Blockchain is carried out by a network of devices and computers known as nodes, each possessing a copy of the same data. Typically, Blockchain infrastructures consist of thousands of nodes. By utilizing nodes, Blockchain technology achieves decentralization, eliminating the need for a centralized server within the network.

To put it simply, Blockchain is a digital system designed to record trade transactions among multiple trading parties in an immutable manner, ensuring the integrity and security of the information exchanged. As a result, identical data copies are stored across various nodes, granting all participants the ability to access them.

While the term blockchain is frequently linked to cryptocurrency, its potential applications extend far beyond that, encompassing a diverse range of possibilities. Indeed, Blockchain grocery endeavors have the potential to revolutionize the grocery industry by offering a secure and efficient method of tracking food items throughout the entire supply chain, from farm to table. Implementing blockchain technology in the grocery sector represents a monumental shift in transforming the conventional industry into a modernized one.

As researched by Demandsage.com , by 2029, the Blockchain industry is projected to reach a value of $163.83 billion, fueled by a remarkable compound annual growth rate of 56.3%. Research and advisory company Gartner has revealed new data indicating that by 2025, approximately 20 percent of the world s largest supermarkets will adopt blockchain technology to enhance visibility into the production, quality, and freshness of their products.

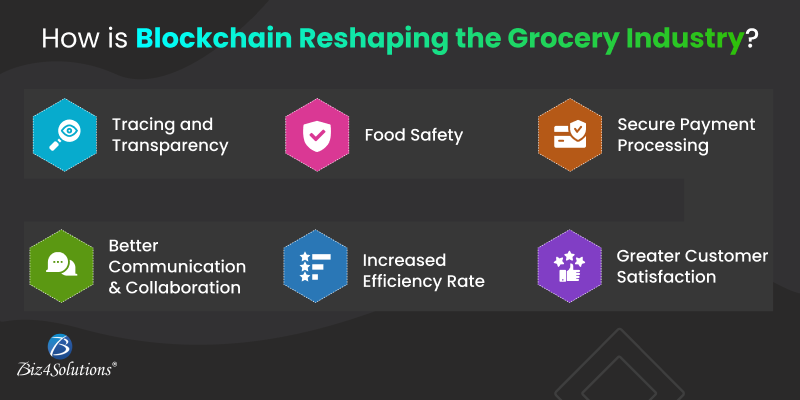

Advantages of Blockchain in the Grocery Sector

Blockchain technology offers numerous advantages that can revolutionize the grocery industry. By harnessing the power of blockchain app development services, businesses in the grocery sector are reaping the benefits. These benefits lead to increased efficiency, trust, and customer satisfaction while addressing critical issues such as food safety, fraud prevention, and environmental impact. Let s explore the specific advantages of Blockchain in the grocery industry.

1. Traceability and Transparency

One of the biggest benefits of blockchain for the grocery industry is its ability to provide traceability and transparency. Blockchain supermarket provides consumers with a means to access comprehensive product information, including details about the origins of the items and the methods used for their cultivation and harvest. The collected data is stored in a secure and unchangeable blockchain.

The implementation of blockchain-based supply chain ledgers enables the identification of food lots that are subject to product recalls. This, in turn, streamlines the process of swiftly removing unsafe food from store shelves, ensuring consumer safety. Equipped with such knowledge, consumers can make well-informed choices when purchasing food and safeguard themselves against the potential risks of consuming harmful products.

The adoption of blockchain in grocery stores, empowers comprehensive traceability throughout the entire grocery supply chain, instilling consumer confidence and trust in grocery brands. Leveraging Blockchain-enabled traceability in the grocery industry, businesses can simplify the task of offering consumers clear visibility into the origins and production methods of their food items and grocery products. So, leading brands are seeking assistance from professional developers to create blockchain-based grocery tracing systems to enhance their reputation and stand out in a competitive market.

For instance, Nestle and Carrefour have collaborated with IBM to establish their dedicated blockchain system, which focuses on new food products. Take the example of Nestle s popular French dish mashed potatoes. The 520g packages of this dish have a barcode that can be scanned by consumers to obtain information like the region where the potatoes were grown, the quality control approaches adopted in Nestle s factory while producing the dish, and the product storage locations and dates before reaching the grocer. As techtarget.com reports, Unilever has implemented SAP s GreenToken to make their palm oil supply chain traceable and transparent. This strategy promotes improving the sustainability of the palm oil manufacturing process.

Such endeavors aim at improving supply chain transparency and demonstrate a food manufacturing company s commitment to enhancing visibility and accountability throughout its operations.

2. Food Safety

In recent years, there have been several high-profile foodborne illness outbreaks that have caused serious illness and even death. As per the U.S Food and Drug Administration (FDA), approximately one in six Americans will experience a foodborne illness annually, resulting in 128,000 hospitalizations and 3,000 fatalities.

Food safety and quality are paramount concerns in the grocery industry. Therefore, by implementing blockchain technology in the food industry, stores can record and track critical information such as batch numbers, expiration dates, and temperature records on the blockchain. Potential issues can be quickly identified and resolved, reducing the risk of foodborne illnesses and increasing consumer confidence.

Blockchain technology plays a crucial role in ensuring the integrity and authenticity of food products. Blockchain supermarkets can enhance food safety by providing transparent and unchangeable transaction records, bringing stakeholders together. Blockchain in the food industry boosts customer trust, and loyalty, and allows easy tracing of food origins improving overall quality and reliability in the industry.

Blockchain supermarket facilitates transparency across the entire food supply chain, enabling real-time information sharing and enhancing supply chain management. Additionally, it generates digital documentation of every food transaction, simplifying the ability to trace the source of wrongdoing and the resulting repercussions. This becomes crucial in an era where food safety is progressively gaining paramount importance.

Presently, major companies such as Unilever, Nestle, and Walmart employ blockchain technology to expedite the detection and elimination of the root causes of foodborne illnesses.

3. Secure Payment Processing

Grocery apps using Blockchain are reshaping payment systems within the grocery industry. Supply chains encompass numerous suppliers, intermediaries, and third-party services, posing difficulties in effectively overseeing the flow of goods, pricing, and supplier payments. Conventional invoice payment terms typically require weeks or even months. However, by employing blockchain-based smart contracts, immediate payments can be facilitated instead. Smart contracts are programmable self-executing contracts on Blockchain. Such contracts can automate payment transfers taking place between suppliers, retailers, and logistics providers based on pre-defined conditions like delivery confirmation. This way, the payment process is executed quickly and securely without the need for involving any intermediaries.

Blockchain technology s decentralized nature offers a transparent payment system, allowing all participants in a supply chain to view payment transactions. This reduces the likelihood of fraudulent practices and human errors. Moreover, blockchain-based cryptocurrencies enable direct payments between supply chain stakeholders, eliminating the need for banks, minimizing transaction fees, and accelerating the payment process. Furthermore, the utilization of Blockchain in the grocery sector can mitigate the risk of fraud and chargebacks, as every transaction is securely recorded on the Blockchain.

4. Better Communication & Collaboration

Blockchain technology has revolutionized communication and collaboration in the grocery industry, providing a more efficient and transparent system for all stakeholders involved. The constant exchange of invoices, order requests, and contracts among different participants in a modern supply chain creates frequent friction and causes unnecessary delays.

However, supply chains that adopt blockchain technology can enhance communication and collaboration among all participants. According to a report by DHL, blockchain enables the sharing of databases among multiple parties, eliminating the necessity for intermediaries to verify, record, or coordinate these transactions. The report states that blockchain facilitates the transition from a centralized to a decentralized distributed system, liberating data that was previously confined in isolated silos.

Blockchain enables seamless real-time sharing of information and data among producers, suppliers, distributors, and retailers, leading to improved coordination and decision-making. By utilizing smart contracts and decentralized ledgers, blockchain eliminates communication gaps, minimizes errors, and builds trust among participants. Its secure and transparent nature facilitates accurate tracking of inventory product quality, delivery schedules, and payments.

5. Increased Efficiency Rate

Blockchain technology has the capability to automatically track the journey of products across the supply chain right from the farm to the shelf. Blockchain records every step including sourcing, processing, packaging, and transportation. Hence, in case of any instance of contamination or a situation when the product has to be recalled, one can effortlessly identify the affected product/s and remove them from the supply chain. This not only reduces the impact on consumer health but also minimizes financial losses for retailers.

Blockchain automation minimizes the risk of human error in the supply chain by streamlining and digitizing data logging. With data stored on the cloud, administrative tasks are reduced, ensuring consistent and accessible data tracking. Instead of having to rely on partner communication, blockchain provides instant access to all product-related information in a distributed database, simplifying communication and operations.

By leveraging blockchain technology, the grocery industry can optimize supply chain processes, automate tasks, and improve data accuracy and transparency. These efficiencies lead to cost reductions, time savings, and streamlined operations, ultimately benefiting both businesses and consumers.

Furthermore, by utilizing blockchain technology in food supply chains, it becomes possible to tackle the issues surrounding food wastage and streamline inventory management, which will ultimately result in better efficiency.

6. Greater Customer Satisfaction

In the current fragmented grocery supply chain, it is often challenging to determine the complete history of a product. Consequently, customers often question the reliability of the information displayed on the packaging. Nevertheless, blockchain in the grocery industry empowers businesses to provide customers with accurate details about the time, location, and method of food processing.

It also enables consumers to trace the product s origin and track its journey, accessing specific information related to each batch. This enhanced transparency has the potential to foster greater trust among customers and cultivate stronger brand loyalty.

Overall, blockchain enhances transparency, traceability, authenticity, customer service, and loyalty programs, contributing to a high level of satisfaction and trust among grocery sector customers.

Are You Interested in Building a Top-Class Website or Mobile App?

In a Nutshell:

In conclusion, blockchain technology brings significant revolutionary benefits to the grocery industry. By harnessing the power of blockchain, businesses in the grocery sector are reaping the benefits of enhanced transparency, improved traceability, efficient inventory management, secure payment processing, and innovative customer engagement. These benefits lead to increased operational efficiency, trust, and customer satisfaction while addressing critical issues such as food safety, fraud prevention, and environmental impact.

The responsibility of providing indisputable evidence regarding the safety of grocery products for consumption is progressively falling on manufacturers and suppliers in many countries around the world. And, Blockchain serves this purpose. It is undeniably a reliable and trusted solution for the grocery industry, mitigating risks, improving data integrity, and fostering trust among stakeholders.

Blockchain apps and solutions will help the grocery industry providers optimize operations, provide greater transparency, and deliver a safer and more reliable shopping experience for everyone involved. So, in a nutshell, it is safe to say that blockchain grocery is the future.